Siding Materials Requiring Extended Installation in 2025

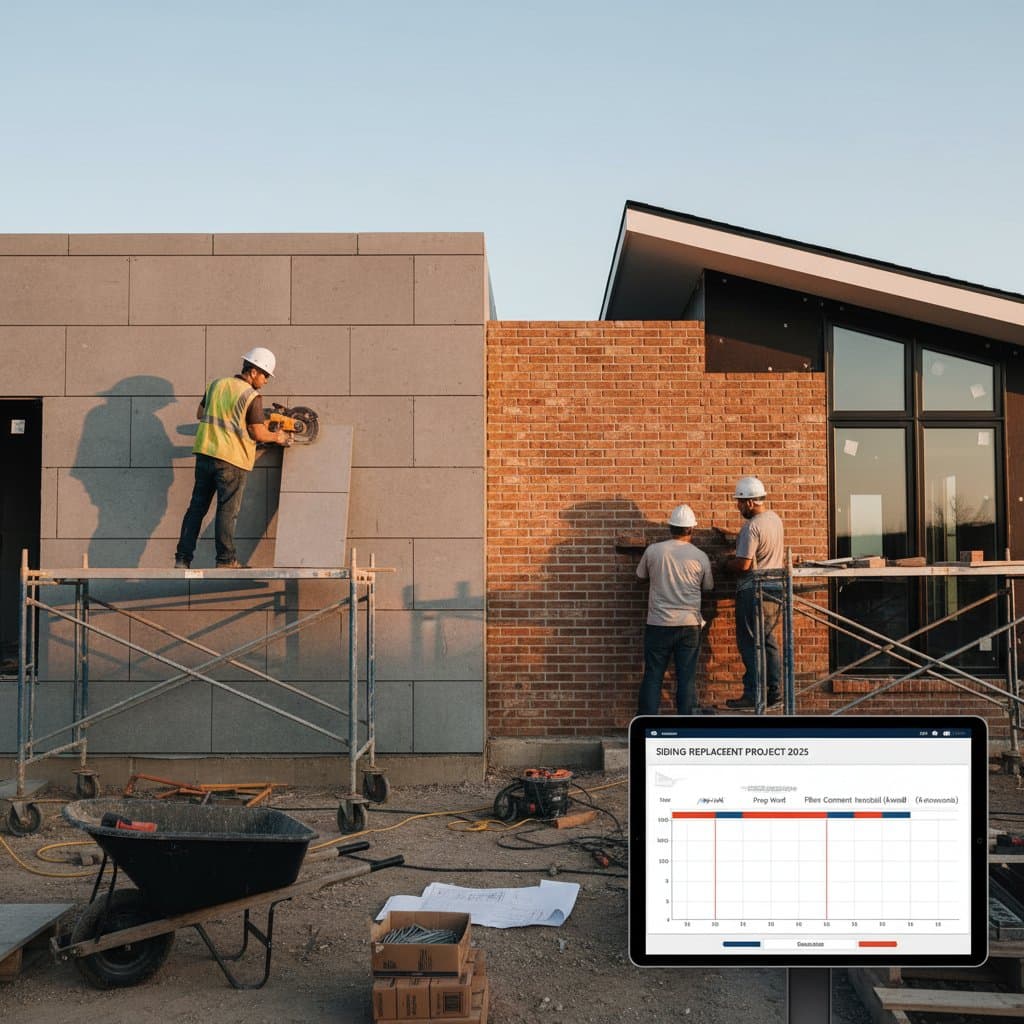

Homeowners frequently prioritize the visual appeal and initial cost of siding, yet installation duration often receives less attention. Materials such as masonry veneer and fiber cement necessitate intricate preparation, specialized equipment, and coordination among trades, which can prolong projects well beyond basic vinyl applications. Understanding these time-intensive options enables better planning for labor expenses, potential weather interruptions, and household disruptions.

This guide examines the factors that extend siding installations, provides budgeting insights, and outlines expectations throughout the process.

Comprehensive Cost and Planning Overview

Project Scope Essentials

Siding replacement typically involves complete removal of existing cladding, trim disassembly, sheathing repairs, and application of new weather-resistant barriers. Additional layers increase overall duration. Options like masonry veneer, fiber cement panels, and natural wood shakes prove particularly time-consuming because of their substantial weight, precise alignment demands, and finishing specifications.

Standard Cost Estimates

- Vinyl siding: $4 to $8 per square foot.

- Engineered wood: $7 to $12 per square foot.

- Fiber cement: $9 to $15 per square foot.

- Natural wood shingles or shakes: $10 to $18 per square foot.

- Brick or stone veneer: $15 to $30 per square foot.

Key Factors Influencing Costs

- Site Access and Elevation: Structures with multiple stories require extensive scaffolding and enhanced safety measures.

- Material Transportation: Dense panels or boards demand team lifts or mechanical aids.

- Substrate Preparation: Addressing rot or replacing sheathing extends preparatory phases.

- Custom Cutting and Alignment: Materials with patterns or offsets require meticulous measurements.

- Environmental Constraints: Applications involving mortar, stains, or paints depend on consistent dry weather.

Full Timeline Breakdown

Standard vinyl installations conclude within one week, whereas fiber cement or masonry efforts may span a month or more. The complete sequence encompasses:

- Bidding and estimation: 1 to 2 weeks.

- Permitting and material procurement: 1 to 3 weeks.

- Demolition and sheathing remediation: 3 to 5 days.

- Core installation and trim work: 10 to 20 days.

- Final inspections and site restoration: 1 to 2 days.

Permitting and Inspection Processes

Local authorities generally mandate permits for comprehensive siding overhauls. Officials verify elements such as moisture barriers, proper flashing, and secure fastening methods. Early coordination of inspection appointments prevents workflow interruptions.

Strategies for Budget Management and Modifications

Request detailed unit pricing for square footage involving sheathing replacements or trim additions to mitigate unforeseen expenses from concealed issues. Refrain from altering materials during execution, as such changes restart procurement delays.

Partial Repairs Versus Complete Overhauls

When damage affects fewer than 20 percent of panels, targeted repairs often prove quicker and more economical. Opt for full replacement in cases of extensive paint degradation, structural rot, or pervasive water damage.

Durability, Safety, and Maintenance Essentials

Mitigating Weather-Related Challenges

In regions with high humidity or proximity to water, intervals for drying between mortar applications or coatings may extend significantly. Both masonry and wood installations require protection from moisture during placement to avoid internal condensation issues.

Performance Against Fire, Moisture, and Impact

- Fiber cement: Provides superior fire resistance with acceptable impact tolerance.

- Engineered wood: Engineered for moisture resistance, though it lacks inherent fire protection.

- Brick and stone: Offer noncombustible properties and robust resistance to wind forces.

- Vinyl: Susceptible to deformation from intense heat exposure.

Critical Building Envelope Practices

Proper flashing around windows and doors, correct overlapping of house wrap, and unobstructed drainage paths behind masonry installations prevent long-term failures. Overlooking or accelerating these procedures frequently results in concealed deterioration.

Recommended Maintenance Routines

- Examine caulk seals annually for integrity.

- Clean exteriors biannually using mild soap solutions and gentle brushing.

- Refresh paint on wood or fiber cement surfaces every 8 to 10 years based on condition.

- Steer clear of high-pressure washing adjacent to joints or mortar lines.

Understanding Warranties and Obligations

Siding warranties primarily address material flaws rather than installation workmanship. Retain documentation including installation photographs and contractor receipts. Utilization of incorrect fasteners or omission of back-side priming may invalidate protections.

Detailed Preparation Steps for Success

1. Establish Project Objectives and Boundaries

Determine whether the initiative calls for a complete material transition or localized updates. Assess requirements for insulation enhancements and moisture control prior to selecting products.

2. Select and Evaluate Contractors

Obtain a minimum of three detailed written proposals. Scrutinize inclusions for demolition, underlying repairs, and trim elements. Inquire about crew size, material expertise, and dedicated timelines.

3. Review Samples and Secure Approvals

Solicit physical samples or minor mockups to evaluate color tones and joint configurations. Provide written consent for corner treatments and trim profiles prior to commencement.

4. Prepare the Site and Accommodate Operations

Ensure unobstructed pathways around the property, relocate delicate plants, and anticipate elevated noise and particulate levels. Accommodate equipment like forklifts by maintaining clear driveways for heavy material delivery.

5. Conduct Milestone Verifications

Examine sheathing fixes before applying barriers. Confirm adherence to nailing standards and joint spacing. Validate flashing installations at openings prior to trim concealment. Capture photographic evidence at each stage to support warranty claims.

Navigating Disruptions in Prolonged Projects

Siding endeavors that extend over weeks introduce notable inconveniences, yet selecting resilient materials yields enduring benefits. Materials such as fiber cement, cedar shakes, and masonry veneer require additional phases for precise layout, secure attachment, and refined completion.

Build in contingencies for variable weather, document agreements meticulously, and maintain regular communication with the installation team. These deliberate choices foster exteriors that withstand time, reducing future maintenance demands and safeguarding your investment.